Mini data loggers help optimise airbags

Recording measured data:

Author: Dipl.-Ing.(FH) Reinhold Steinlechner, efficiency - Ingenieurbüro, Jenbach, Austria

Airbags for fun sports such as platform diving, free climbing, snowboarding or BMX, must meet the highest safety requirements. Developers at the Austrian Airpatrol Company used MSR data loggers to calculate and analyse the g-forces that impact upon the jumper when landing on the airbag.

When a stuntman in a film saves himself by jumping out of the window of a burning house, he is caught by an airbag below the window – it is quite possible that the latter was manufactured by Airpatrol. This Austrian company has been developing and producing airbags for a number of years. Among other things, it also developed the “AIR2BAG” airbag, which has established itself in the freestyle scene. This oversized airbag is, for instance, used during fun sports events.

Safety comes first

Airpatrol concentrates on the safe application and design of airbags and has developed a safety and monitoring system specifically for this. The “Airbag Analyzer” for the operation of airbags was developed by Airpatrol in close co-operation with the Austrian Technical Inspection Authority, TÜV, and signalises the operational readiness of airbag to the jumpers by means of audio-visual signals. The physical stress on the user – which acceleration forces are they exposed to? – plays a crucial part with respect to the safety of airbags. Data loggers by MSR Electronics can be used to measure the g-forces, which impact upon the jumper when landing on the airbag with high precision. For fast recording at 1600 Hz in three axes, Airpatrol uses the MSR 165 shock data logger with an external 3-axis acceleration sensor. This data recording device, which is barely the size of a thumb, facilitates monitoring shocks up to ±15 g; ±200 g would also be possible. The memory is capable of storing over two million measured values, which is sufficient for recording more than 10,000 shocks; the memory capacity of the logger can be extended to more than 1 billion measured values by using a microSD card. The measured data of the transmitter modules recorded by the data logger can be read out via a USB interface and processed further using the MSR PC software for data analysis purposes.

Airpatrol concentrates on the safe application and design of airbags and has developed a safety and monitoring system specifically for this. The “Airbag Analyzer” for the operation of airbags was developed by Airpatrol in close co-operation with the Austrian Technical Inspection Authority, TÜV, and signalises the operational readiness of airbag to the jumpers by means of audio-visual signals. The physical stress on the user – which acceleration forces are they exposed to? – plays a crucial part with respect to the safety of airbags. Data loggers by MSR Electronics can be used to measure the g-forces, which impact upon the jumper when landing on the airbag with high precision. For fast recording at 1600 Hz in three axes, Airpatrol uses the MSR 165 shock data logger with an external 3-axis acceleration sensor. This data recording device, which is barely the size of a thumb, facilitates monitoring shocks up to ±15 g; ±200 g would also be possible. The memory is capable of storing over two million measured values, which is sufficient for recording more than 10,000 shocks; the memory capacity of the logger can be extended to more than 1 billion measured values by using a microSD card. The measured data of the transmitter modules recorded by the data logger can be read out via a USB interface and processed further using the MSR PC software for data analysis purposes.

Evaluating the load curve, calculating the jump height

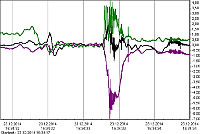

The aim of the AIR2BAG measurements recently performed by Airpatrol was to record the load curves of the jumpers and to calculate the limits of the jump height. During the jumps, the test subjects wore the data logger strapped to their lower leg. At the same as recording the measured data, a high-speed camera filmed the exact landing position of the jumper and subsequently compared it with the measured acceleration trend. The data logger was also used to measure rotary movements of the jumper in the air and to analyse them in the representation of the 3-axis trend.

The aim of the AIR2BAG measurements recently performed by Airpatrol was to record the load curves of the jumpers and to calculate the limits of the jump height. During the jumps, the test subjects wore the data logger strapped to their lower leg. At the same as recording the measured data, a high-speed camera filmed the exact landing position of the jumper and subsequently compared it with the measured acceleration trend. The data logger was also used to measure rotary movements of the jumper in the air and to analyse them in the representation of the 3-axis trend.

Based on the recorded measured values, Airpatrol was able to ascertain that, at a defined jump height, the measured acceleration trends on impact are largely harmless. Furthermore, analysing the measured data enables the company to further optimise the AIR2BAG, therefore facilitating an even gentler landing on the airbag at even lower load.

Can we also help you with your measuring tasks? We would be pleased to advise you!

Deutsch

Deutsch