MSR Mini Data Loggers optimise transports

Recording measured data:

The following report was published in the September 2015 edition of the Elektronik, Sonderheft messen+testen (Electronics, measuring+testing special edition) magazine.

It goes without saying that quality assurance is one of the most important factors during the production of precision measuring instruments. What happens, though, once these highly sensitive devices leave the factory? Miniature data loggers can help assure the quality along the route of transport.

Trimos SA, which has been active in industrial metrology since 1972, manufactures a wide range of products in the field of dimensional metrology: height gauges, horizontal length measuring and calibrating equipment and non-contact surface measuring instruments. Trimos precision measuring instruments are, for example, used in machine building for measuring all kinds of parts. All instruments are developed and manufactured in the production halls in Renens near Lausanne. The company’s export rate is at a high 95 %; therefore, the company is anxious to organise the transport routes in a way that allows them not to worry about any damage to the devices. As a result of regular evaluations of customer service data and complaints, the company had already realised that in most cases, product complaints were not due to material or manufacturing defects but to damage caused during transport. This did not only result in customers becoming agitated, but in many cases it proved difficult for Trimos to hold the responsible carrier liable for the damage. Therefore, in order to maintain customer satisfaction, Trimos usually bore the cost for repairs itself instead of passing them on to the person responsible. The consequences for Trimos were complex: high costs, as well as a loss of time and a tarnished image.

Trimos SA, which has been active in industrial metrology since 1972, manufactures a wide range of products in the field of dimensional metrology: height gauges, horizontal length measuring and calibrating equipment and non-contact surface measuring instruments. Trimos precision measuring instruments are, for example, used in machine building for measuring all kinds of parts. All instruments are developed and manufactured in the production halls in Renens near Lausanne. The company’s export rate is at a high 95 %; therefore, the company is anxious to organise the transport routes in a way that allows them not to worry about any damage to the devices. As a result of regular evaluations of customer service data and complaints, the company had already realised that in most cases, product complaints were not due to material or manufacturing defects but to damage caused during transport. This did not only result in customers becoming agitated, but in many cases it proved difficult for Trimos to hold the responsible carrier liable for the damage. Therefore, in order to maintain customer satisfaction, Trimos usually bore the cost for repairs itself instead of passing them on to the person responsible. The consequences for Trimos were complex: high costs, as well as a loss of time and a tarnished image.

Data Loggers for objective recording of measured values

Therefore, the aim was to uncover the causes of the damage and to optimise the processes. In order to be able to assess the transportation stresses in more detail in the future, Trimos decided to carry out trial deliveries using data loggers. The Lausanne-based company selected the MSR165 mini data loggers of MSR Electronics GmbH for this purpose. The sensitive 200 g sensor registers accelerations, which arise when the logger is in motion, in all three axes: forward/backward (x), right/left (y), up/down (z). As the data logger also measures the gravitation, the actual position can be determined as well. By determining the position and the acceleration forces, the data analysis can be used to identify which stresses the cargo was exposed to. In order to also record the temperature profiles, the MSR165 transport data logger was additionally equipped with a temperature sensor for use at Trimos.

What happens to the cargo when, where, how often and to what extent?

The MSR165 documents every change, be it ever so small, recording the exact time of occurrence. On the basis of a detailed study it was established what exactly happens during the transports and which adjustments – with respect to the packaging, the route and the means of transport – will be necessary in the future.

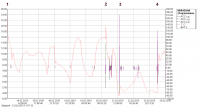

By means of the MSR PC software affiliated with the logger, the desired settings for the data recording are selected. The recording can be started via the program or using the button on the data logger. The latter proved convenient during the tests as this way, the recording can be started at any time and there is no need to pay attention to shocks during the installation. An initial test series aimed at testing the properties of the packaging.  These tests consisted of dropping a packaged, highly sensitive height gauge under different conditions (height, position of the point of impact etc.) in order to simulate the events taking place during the transport. The tests revealed the weaknesses of the packaging, enabling Trimos to implement improvements. Once the internal tests had been successfully concluded, the test phase was launched under real conditions. The MSR165 data logger was attached directly to a Trimos device during the packaging process shortly before shipment. Subsequently the cargo, including the loggers, was sent to a number of critical places of delivery in order to evaluate the shocks and differences in temperature incurred during the transport. On average, the data logger remained on the cargo for 10 days between leaving the factory and arriving at the destination. As the chart of a typical transport procedure shows, the highest stresses occurred on the y-axis and the differences in temperature were distinctive.

These tests consisted of dropping a packaged, highly sensitive height gauge under different conditions (height, position of the point of impact etc.) in order to simulate the events taking place during the transport. The tests revealed the weaknesses of the packaging, enabling Trimos to implement improvements. Once the internal tests had been successfully concluded, the test phase was launched under real conditions. The MSR165 data logger was attached directly to a Trimos device during the packaging process shortly before shipment. Subsequently the cargo, including the loggers, was sent to a number of critical places of delivery in order to evaluate the shocks and differences in temperature incurred during the transport. On average, the data logger remained on the cargo for 10 days between leaving the factory and arriving at the destination. As the chart of a typical transport procedure shows, the highest stresses occurred on the y-axis and the differences in temperature were distinctive.

The evaluation of this measured data showed that the most severe shocks occur while handling the cargo and during the final transport. However, the optimised packaging had shown the properties required in order to protect the device against shocks in the most critical direction (y). Measures for optimising the selection of the local carriers were taken. By using the MSR165, the values concerning the optimised packaging of the new Trimos height gauge family were efficiently measured and analysed. Numerous doubts with respect to its ability to absorb shocks during transport were removed this way.

Therefore, data loggers are able to support the quality assurance to the effect that, with their objective measured values, they provide clear facts instead of allowing vague speculations to prevail. The documentation of events causing damage not only ensures that the causes of the damage are identified quickly and the costs can be passed on, but the early detection of damage is also a prerequisite for meeting time-critical delivery deadlines and preventing a tarnished image. Not least, the data loggers deliver valuable measured data for optimising packaging, as well as means and routes of transport.

Can we also help you with your measuring tasks? We would be pleased to advise you!

You may also be interested in these articles:

- MSR165 Data Logger for shock and vibration

- Collecting data for secure transportation

- Monitoring of various precision machines in transit – MSR165 Data Logger in use

- Precise recording of dynamic mechanical stress: MSR165 Data Loggers assist with machine, workpiece and production optimisation

- Determining transportation stresses when shipping pallets or individual packages – user report by Alfred Kärcher GmbH & Co. KG

- The fast way to the right Data Logger

Deutsch

Deutsch