Use of MSR Data Loggers at Uroviva Services AG, Bülach, Switzerland

Authors: Dirk-Marcus Walenzki, Franziska Rüesch, Peter Meierhans, Uroviva Services AG, Bülach

Professional transport of sensitive, high-tech medical devices within operating rooms and between hospitals and clinics requires high level of competence and modern transport logistics. Uroviva Services AG specializes in transport of medical devices and uses data loggers from MSR Electronics GmbH for quality assurance. Using the data loggers they can verify when and where the cargo has been subjected to shocks and whether their intensity may have affected the smooth functioning of the highly sensitive, high-tech devices.

There is a constant increase in the number of road transportation of highly sensitive medical devices and supplies nationwide. The sensitive, high-tech devices are therefore exposed high levels of stress and risks such as shocks and vibrations. The loading and reloading of the devices and moving them within the operating rooms of hospitals and clinics, the truck journeys over bumpy roads and forecourts are typical risk situations which may result in damage to the devices.

The Uroviva Services AG has set itself the goal of transporting such highly sensitive, high-tech medical devices from A to B using advanced transport logistics. Based in Bülach, Switzerland, the company is part of Uroviva Network, the renowned competence-centre for urology which with its various sites and with approximately 9,000 patients annually is one of the key components of the urological care in the Canton of Zurich.

Transport monitoring for quality assurance and best practice evidence

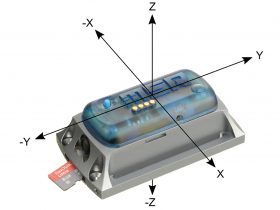

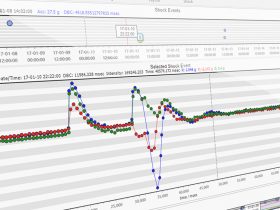

Uroviva Services AG uses autonomous MSR165 data loggers with integrated 3-axis accelerometer for the monitoring of the demanding transport of sensitive medical devices and the comprehensive recording of blows, shocks and vibrations. The highly sensitive sensor records the accelerations in all three axes: front-back (x), right-left (y), up-down (z). Since the data logger is subjected to a permanent gravity (gravitational acceleration), one can also determine the actual position as well. Once the position and the acceleration forces have been determined the data analysis can reveal which kind of stress the cargo has been exposed to. In principle, and depending on the choice of sensors, one can use MSR165 both for measuring direct impact on the cargo, e.g. forces and accelerations, as well as the indirect factors such as temperature, humidity, pressure, or light. If no threshold values are set, the MSR165 provides continuous transport measurements of up to 3 days, at a measuring rate of 1600 measurements per second. If threshold values are set, the MRS165 Data Loggers can be used for monitoring of shocks for up to six months. The user has an optional autonomous charging station or long-life batteries at his disposal for an even longer period of recording. Shock monitoring is possible with the MSR165 either for ± 15g or ± 200g. 32 measurements are recorded prior to the event. While logger’s storage capacity of two million measurement values suffices for standard recording of over 10,000 blows, Uroviva Service AG utilizes the version with expanded memory for its application. Hence, its loggers have a storage capacity of over one billion readings. MSR165 can be mounted directly onto the casing of a mobile device thanks to the very small external dimensions, light weight and the built-in sensors and power supply in the data logger itself. There is no need to install cables which would be a hindrance during transportation. The battery can be charged via the USB port of a notebook and the measuring parameters can be programmed simultaneously, facilitating the handling of the data logger.

For purposes of quality assurance and best practice evidence, Uroviva Services AG uses a MSR165 data logger for every consignment. This ensures that shocks impacting the cargo during the entire journey over country roads, motorways and in city traffic are recorded. Using the continuous recording and documenting, the company can verify at all times when and where has the cargo been subjected to blows or shocks and whether their intensity may have affected the smooth functioning of the highly sensitive, high-tech devices. Based on the measured data and transport route recorded during transport and loading process one can significantly optimize the transport route, means of transportation and securing of the cargo.

Swiss Television SRF reported in its economy show „Eco“ regarding the use of the MSR165 data loggers at Uroviva Services. The report about Uroviva starts at 3’38.

Deutsch

Deutsch