Detecting and Preventing Transport Damage with the MSR165 Data Logger

User Report – Qingdao Hisense Hitachi Air Conditioning Systems Co., Ltd.

When transporting air conditioning units, vibrations, shocks or improper handling can cause damage – often without this being immediately apparent from the outside. To monitor such risks and ensure product quality until delivery, Hisense uses MSR165 shock and vibration data loggers, which continuously record transport conditions. The data obtained provides valuable insights for product development and quality assurance: it enables problems observed in the market to be specifically reproduced under laboratory conditions, the causes of defects to be identified and design weaknesses to be permanently remedied.

Author: Li Xiaobing, Hardware Test Engineer, Qingdao Hisense

Qingdao Hisense Hitachi Air-conditioning Systems Co., Ltd., based in Qingdao, Shandong Province, is a global unit of Hisense Group Co., Ltd. in cooperation with Hitachi, Ltd. The company develops and manufactures central air conditioning systems (VRF, air/water systems, etc.) for the international market.

During transport of the outdoor units of central air conditioning systems, mechanical stresses such as impacts or vibrations can occur, leading to sheet metal deformation or damage to pipes. Such damage is often not immediately apparent, but it does lead to complaints and high follow-up costs. If an outdoor unit is damaged and has to be replaced or returned, the costs can quickly run into tens of thousands of Yuan. In addition, such incidents can have a lasting negative impact on the product reputation and image of the company.

To counteract these risks and take real transport stresses into account in the development process, a reliable method of long-term recording of shock and vibration data was needed. Qingdao Hisense Hitachi therefore uses the MSR165 shock and vibration data loggers to accurately record transport conditions and precisely reproduce the data obtained in laboratory tests.

Understanding transport stresses – thanks to precise measurement data

By attaching the MSR data loggers to the base plate structure of the outdoor units, the vibration data is recorded during actual transport. Integrated sensors continuously record acceleration, shocks, temperature and humidity. This provides a complete picture of the actual transport conditions – from production to delivery.

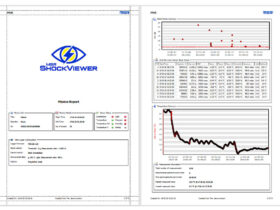

The recorded measurement data is then subjected to a detailed time history analysis and used to create PSD (power spectral density) spectra. These analyses enable engineers to precisely replicate real transport loads in the laboratory and derive targeted optimisations for design, packaging and material selection.

Based on this data, defects observed in the field – such as copper pipe breaks or sheet metal cracks – can be reproduced and analysed under laboratory conditions. The PSD spectrum obtained in this way can also be used in the development of new products to identify potential weak points at an early stage and to calibrate test conditions realistically.

In addition, the MSR165 data loggers record temperature and humidity data during storage and transport. This information is used to review and optimise existing test standards for climatic storage conditions and helps to verify temperature and humidity requirements in transport and storage processes.

MSR165 data logger: Proven measurement solution for transport and development processes

When selecting a suitable data logger, Hisense Hitachi focused on measurement precision, reliability and efficient data evaluation. Compared to other compact data loggers available on the market, the MSR165 impresses with its high sampling rates and thus particularly precise measurement data, which remain reliable even during long-term data acquisition. The ability to analyse PSD spectra (power spectral density) also forms an important basis for evaluating real-world loads and simulating them in the laboratory.

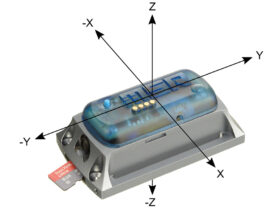

Thanks to its compact design, waterproof, anodised aluminium housing and low energy consumption, the MSR165 shock and vibration data logger can be used reliably even under demanding operating conditions. An integrated lithium battery (1000 mAh) enables continuous recording for up to six months – a decisive advantage for long transport and delivery cycles of central air conditioning units. Battery charging and data readout are conveniently carried out via USB.

Depending on the application, the MSR165, manufactured in Switzerland by MSR Electronics GmbH, is equipped ex works with an internal or external ±15 g or ±200 g 3-axis acceleration sensor. The measurement and storage rate can be flexibly set between 25 Hz and 1600 Hz, enabling both continuous vibration measurements and the recording of individual shock events, with 32 measured values already stored before the event. In addition, up to four additional sensors – for example for temperature, air pressure, relative humidity or light – can be integrated.

With a storage capacity of over two million measured values, optionally expandable to more than one billion values via microSD card, the MSR165 supports long-term recordings over several months or even years. Approved by numerous airlines for air cargo transport (air cargo approved), it is also suitable for international transport. The free MSR PC software enables easy configuration and evaluation, while the ShockViewer software provides detailed analysis of shock and vibration events.

Supported by the expert advice of Hongke, MSR sales partner in China, Hisense Hitachi was able to optimally integrate the MSR165 data logger into existing testing and analysis processes. The result is a reliable, proven solution that delivers consistent data and provides valuable insights for product optimisation.

Results and benefits

The use of the MSR165 shock and vibration data logger enables Hisense Hitachi to objectively record and evaluate the stresses that occur during transport. On this basis, critical points in the design and packaging can be identified at an early stage, transport conditions can be simulated realistically in the laboratory and the risk of complaints can be significantly reduced.

The data obtained also provides valuable insights for product development: design and packaging solutions can be specifically adapted to real-world stresses at an early stage. This leads to more efficient development processes, more robust assemblies and sustainably higher product reliability.

In quality assurance, the measurement data is used to specifically reproduce problems observed in the market under laboratory conditions. In this way, the causes of defects can be clearly identified and design weaknesses specifically remedied.

According to the manufacturer, this saves the company around 2 million RMB annually, as potential field problems are identified and remedied as early as the development phase.

«Compared to other data loggers, the MSR165 offers a higher sampling rate and significantly more precise data acquisition, making it ideal for long-term measurement of transport loads. In combination with the evaluation software, professional and accurate PSD spectra can be created.» Li Xiaobing, Hardware Test Engineer

MSR transport data loggers customer reports

ORBITAL SCI.: MSR165 DATA LOGGERS MONITOR NASA TRANSPORT

Read MoreWAFER TRANSPORT MONITORING WITH MSR175PLUS DATA LOGGER

Read More

SHOCK DATA LOGGERS MONITOR TRANSPORT OF MACHINES

Read More

MSR165 LOGGERS DETERMINE RAIL TRANSPORTATION COMFORT FOR STADLER RAIL

Read More

CTI RESEARCH PROJECT: PREVENTION STRATEGIES IN THE TRANSPORT OF FRAGILE PAINTINGS

Read More

MSR165 SHOCK LOGGER FOR TEST TRANSPORTS OF FRAGILE PAINTINGS

Read More

UROVIVA: DATA LOGGERS MONITOR TRANSPORT OF MEDICAL EQUIPMENT

Read More

WEGMÜLLER AG: TRANSPORT MONITORING WITH MSR DATA LOGGER

Read More

MONITORING TRANSPORT LOADS WITH MSR DATA LOGGERS

Read More

IPC HORMANN: DATA LOGGERS FOR TRANSPORT MONITORING

Read MoreCERN: TRANSPORT MONITORING WITH MSR175PLUS LOGGERS

Read More Deutsch

Deutsch