Modular clamping system

The acceleration data logger MSR165 monitors process dynamics during the machining of CFRP parts.

The Department of »Light-weight Construction Technology« at the German Fraunhofer Institute for Manufacturing Engineering and Automation (IPA) are experts in light-weight construction and sawing technology which includes machining of light-weight construction materials such as carbon fibre and glass fibre reinforced plastic. In addition to the machining process and its sub-processes, the department also focuses on extraction technology, tool design, digitalisation, cooling and lubrication systems, together with robotised machining.

Author: Thomas Götz, M. Sc., Research Assistant in the »Light-weight construction technology« department of the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA)

Building components made of carbon fibre reinforced plastic (CFRP) are manufactured using near net shape techniques however they also have to be machined around the edges and in order to improve their functionality may also need to insert drill holes. Due to the mainly open and large-scale design of the components they are often unstable and tend to suffer vibration despite the high level of stiffness. Consequently, the service time of the used tools and the processing quality are impacted.

To avoid such effects during machining, it is normal to use clamping templates showing a negative image of the CFRP component. Thus, the component is fully supported, and can be clamped free of vibration in a vacuum. A disadvantage of this method is that the clamping template can only be used for one component geometry. Even the slightest change to the construction of the component blank may require a new construction.

As part of the research project sponsored by the Federal Ministry of Education and Research CFK Complete, a modular clamping system was developed that can be used for the final processing of different geometries of CFRP components. This clamping system comprises several units of freely configurable vacuum clamps with lockable support pins (see image 1) depending on the geometry, and can be easily adjusted to very different component contours.

Modular tensioning system

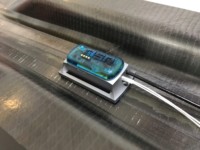

To check how suitable a modular clamping system is for the machining of CFRP components, the dynamic behaviour of the work pieces clamped with the clamping system was recorded during the processing of the component contour using the acceleration data logger MSR165. The accelerometer was placed in the middle of the component and fixed mechanically with screws (see images 2a and 2b). The dynamic behaviour was then compared with that of the work piece clamped with the conventional template.

Fixing the acceleration data logger

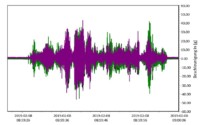

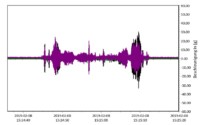

Tests have shown that the work pieces exhibit a much stronger dynamic behaviour during the processing of the contour when they are clamped with a modular clamping system than when they are clamped with a conventional clamping template (see images 3a and 3b).

The results can be explained by the fact that the modular clamping system offers a smaller supported area compared to the clamping template resulting in the component exhibits stronger vibrations due to the dynamic influences of the machining forces. Consequently, the tool life is shorter and the processing quality is lower. In view of this, the modular clamping system is a viable alternative in particular for small quantities and the construction of prototypes, while a conventional clamping template is preferable for a larger number of pieces and volume manufacture.

Can we also help you with your measuring tasks? We would be pleased to advise you!

You may also be interested in these posts:

- Configure your own custom MSR165 Data Logger variant

- Precise recording of dynamic mechanical stress: MSR165 Data Loggers assist with machine, workpiece and production optimisation

- Vibrations: where, how and to what extent? User report MSR165 Data Loggers at u-blox AG

- MSR165 Data Loggers to detect machine trouble quickly and accurately

- The fast way to the right Data Logger

Deutsch

Deutsch