Data Logger for transport monitoring:

MSR Mini Data Loggers determine the causes of damage during transit

In globalised markets industrial commodities and goods of all kinds have to be shipped around the world. During such goods transports, particularly if they span several continents, a great deal can happen: High temperatures, inadmissible humidity values and mechanical shock events are only a few examples of damage events, resulting not only in hassle but also additional expense. However, compact data loggers for transport monitoring can help to accurately analyse the causes of damage during transit and to identify the parties responsible.

If damage has occurred as a result of unfavourable environmental or transport conditions, you can ascertain retrospectively what happened at which point in time, provided that during the transport, critical environmental parameters were recorded. Some companies even define particular environmental specifications for shipping delicate goods, which must then be monitored. If subsequently, damage can be proven accurately, this makes it easier in any case to answer questions relating to liability and quality assurance or to at least provide information on how to prevent problematic transportation conditions in the future.

Monitoring and documenting transportation problems

The Swiss company Belimo Automation AG, which has printed circuit board assemblies for heating, ventilation and climate controls produced in China and in the Philippines, has had issues with problematic transportation conditions. Once a week a standard container, loaded with products for this company only, arrives in Switzerland, following an approximately six-week sea voyage and subsequent land transport. The printed circuit boards stored in the containers in cardboard boxes and blister packaging are especially sensitive towards exposure to humidity. In particular, it is the slide switches and plug-in connectors on the printed circuit boards that would be damaged by excessively high moisture levels or even direct exposure to water.

Exactly such a case occurred some time ago, so Belimo decided to employ the MSR145 miniature data loggers by MSR Electronics GmbH based in Seuzach (Switzerland), which were already known in the in-house research department, in order to monitor and document the temperature and humidity conditions prevailing during the transport by packing them in the transport containers. This way Belimo wanted to provide evidence to the logistics company responsible in the event of further damage.

Analysing measured values in every detail

The MSR145 data loggers, which are merely the size of a thumb, store more than two million measured values – with an optional microSD card, even over a billion measured values – and are perfectly suited for long-term measurements during transports. They are capable of simultaneously measuring and storing the five crucial physical measurands temperature, humidity, air pressure, location/3-axis acceleration and light. Subsequently, for data analysis purposes, all measured values can be transferred to a computer via the USB port or microSD card and analysed in every detail using the “MSR Viewer” software. These loggers are available in different versions and can be customised. In addition, analogue inputs allow you to connect individual, external sensors for different measuring tasks (e.g. CO2 level, conductivity, pH value etc.).

The MSR145 data loggers, which are merely the size of a thumb, store more than two million measured values – with an optional microSD card, even over a billion measured values – and are perfectly suited for long-term measurements during transports. They are capable of simultaneously measuring and storing the five crucial physical measurands temperature, humidity, air pressure, location/3-axis acceleration and light. Subsequently, for data analysis purposes, all measured values can be transferred to a computer via the USB port or microSD card and analysed in every detail using the “MSR Viewer” software. These loggers are available in different versions and can be customised. In addition, analogue inputs allow you to connect individual, external sensors for different measuring tasks (e.g. CO2 level, conductivity, pH value etc.).

In the specific case of the sea/land transport of the Belimo products from the Far East to Europe, only the parameters “humidity” and “temperature” need to be recorded. The MSR data loggers could do this at one-second intervals; however, the programming specified at the head office in Hinwil defines a logging interval of one minute, which is perfectly sufficient.

When loading the containers, a specifically trained employee of the Asian production company packs a logger together with the printed circuit boards and places this cardboard box at the top inside the container. Prior to this, they press the “Start” button on the logger to start the measuring cycle.

Accurately diagnosing the impact of damage

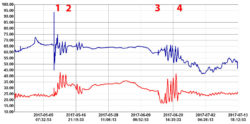

Following the transport, when the container has arrived and is opened at Belimo in Hinwil, the data logger is removed and its data record is examined using the “MSR Viewer” analysis software. The measured temperature and humidity values recorded at one-minute intervals during the entire transport are now shown in a clear chart; the time at which each value was recorded can be read accurate to the second. Using the logger data, you can determine accurately whether or when exactly damage has occurred. In this specific case the temperature value is of secondary importance as the printed circuit boards are already specified to be stored at temperatures of up to 50 °C.

“This way we are able to identify exactly on which section of a route of transport a temperature overload or exposure to humidity occurred. It is then relatively easy to allocate such an event to the respective logistics company responsible, using the point in time of the recording,” explains Beat Kuster, who is jointly responsible for “lifecycle” issues in the electronics development department at Belimo. “Therefore, we are very pleased with the loggers. In the past we suffered a major loss, where we had to remove all printed circuit boards from their blister packaging, check and dry them as they had been exposed to water.“

“This way we are able to identify exactly on which section of a route of transport a temperature overload or exposure to humidity occurred. It is then relatively easy to allocate such an event to the respective logistics company responsible, using the point in time of the recording,” explains Beat Kuster, who is jointly responsible for “lifecycle” issues in the electronics development department at Belimo. “Therefore, we are very pleased with the loggers. In the past we suffered a major loss, where we had to remove all printed circuit boards from their blister packaging, check and dry them as they had been exposed to water.“

Ultimately, the small MSR145 transport monitoring data loggers – meanwhile approximately 30 of them are used by Belimo in rotation – cannot prevent damage to or impairment of the goods during transit. However, they can contribute to ensuring that logistics companies handle the goods entrusted to them with greater care and that in the event of damage or loss, the perpetrator can be located accurately. Furthermore, the detailed analyses of the data loggers can provide significant support during legal disputes.

Can we also help you with your measuring tasks? We would be pleased to advise you!

You may also be interested in these articles:

- MSR145: The revolutionary mini Data Logger

- Collecting data for secure transportation

- Monitoring of various precision machines in transit – MSR165 Data Logger in use

- Determining transportation stresses when shipping pallets or individual packages – user report by Alfred Kärcher GmbH & Co. KG

- The fast way to the right Data Logger

Deutsch

Deutsch