NEW MSR175Pro: Transport Shock Monitoring Data Logger for Heavy-Load and Transformer Shipments

3-axis acceleration sensor with selectable measuring ranges ±10 g, ±20 g or ±40 g · signal filtering · temperature, humidity, air pressure and light sensors · memory capacity: 2 million measurement values

The MSR175Pro is designed for monitoring mechanical shock and impact loads in demanding transformer and heavy-duty transport applications. The robust data logger provides objective, traceable measurement data for evaluation of transport related stresses and for the factual assessment in case of damage.

Based on the proven technology of the MSR175 series, the MSR175Pro has been specifically developed for transport applications involving high masses and short-duration, highly dynamic shock events. The integrated 3-axis acceleration sensor with selectable measuring ranges of ±10 g , ±20 g, and ±40 g reliably records both low-frequency transport loads and short-duration shock events. Selectable sampling rates from 4 Hz to 4000 Hz, combined with anti-aliasing, decimation and high-pass filters, enable clean separation of relevant shock signal components from static acceleration influences. This allows transport-induced loads to be technically assessed correctly and misinterpretations caused by gravitational acceleration or vehicle motion to be avoided.

Tamper-proof event recording and reliable data

The event-based data storage with shock thresholds selectable in defined increments from 0.5 g and a separate auxiliary memory that can not be overwritten ensures that critical transport loads are recorded completely and tamper-proof. The recorded time histories and directional information allow precise reconstruction of the load situation and provide a reliable data basis for damage analysis, acceptance procedures and the technical clarification of liability and insurance matters.

Software package included in delivery

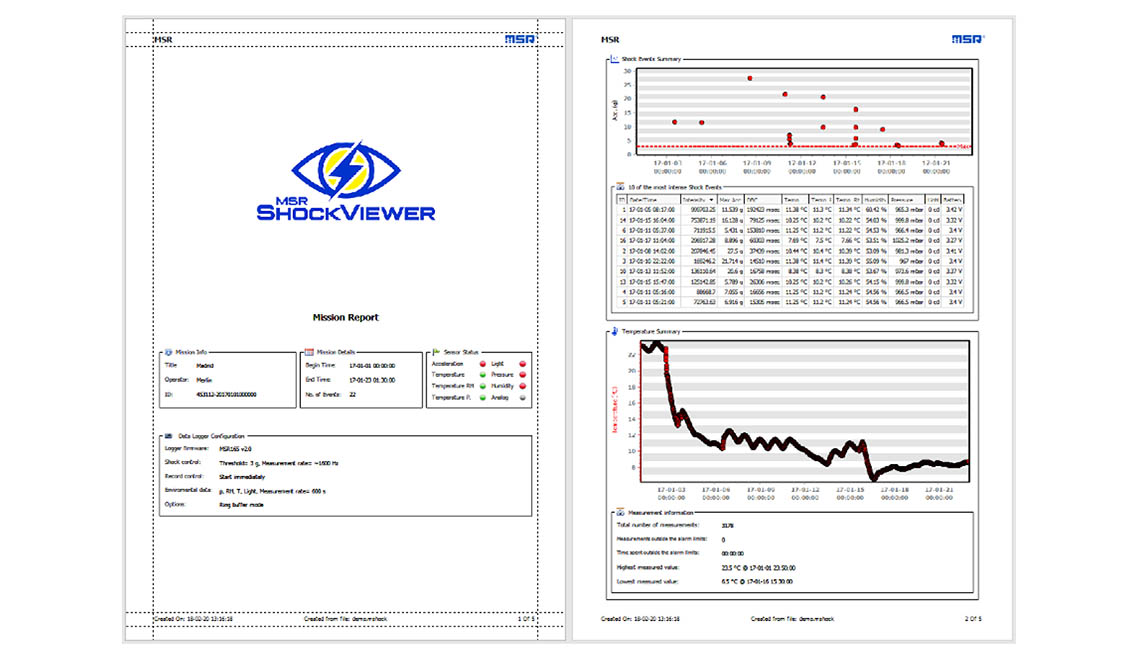

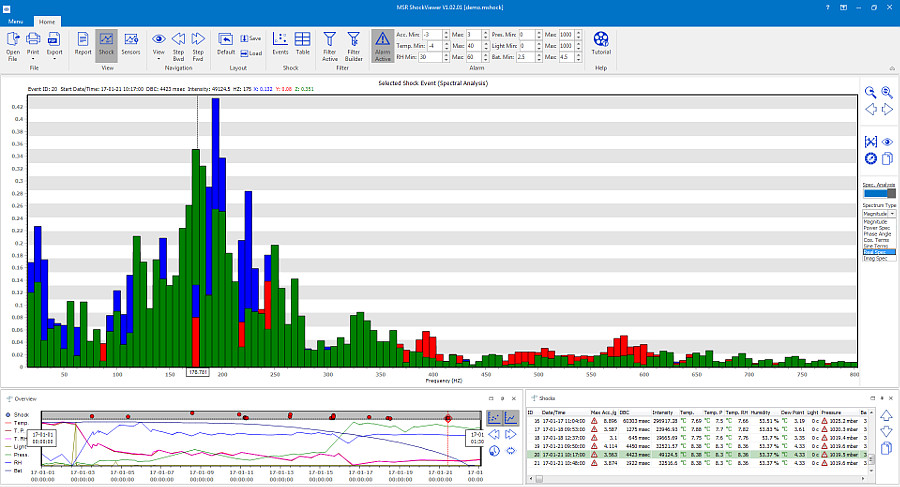

The MSR175 software package supports all data loggers of the MSR175 product family, including the MSR175Pro, and is used for configuration, evaluation and documentation of the recorded measurement data. It enables efficient processing of large data volumes and traceable analysis of transport-relevant events.

Three powerful software tools are included:

• MSR Dashboard for straightforward configuration of the data loggers, management of multiple devices and rapid data readout via USB

• MSR ReportGenerator for automatic creation of transport-relevant reports

• MSR ShockViewer for detailed analysis, visualisation and evaluation of shock profiles and dynamic events

| Item no. | Sensors | Housing & battery | CHF (net) |

|---|---|---|---|

175B54T9AA6PRO

|

|

PC, encapsulated, IP65, replaceable battery (SAFT LSH 14, 3.6 V, 5.8Ah) Size (W x H X L) & Weight: 49 x 39 x 122 mm, approx. 180 g |

CHF CHF 816.00 buy online contact a reseller |

175B54T6H3P5AA6L3PRO

|

|

PC, encapsulated, IP65, replaceable battery (SAFT LSH 14, 3.6 V, 5.8Ah) Size (W x H X L) & Weight: 49 x 39 x 122 mm, approx. 180 g |

CHF 976.00 buy online contact a reseller |

Product features MSR175Pro transport data logger

Reliable shock and climate monitoring for heavy-load transport

- Integrated in-housing 3-axis acceleration sensor with selectable measuring ranges of ±10 g, ±20 g or ±40 g

- Adjustable measurement and recording rates: 4 Hz, 8 Hz, 16 Hz, 31 Hz, 62 Hz, 125 Hz, 250 Hz, 500 Hz, 1000 Hz, 2000 Hz, 4000 Hz

- Multiple shock measurement modes

- Anti-aliasing and decimation filters for signal conditioning

- High-pass filter for removal of static acceleration (gravitational component)

- Shock thresholds adjustable in 0.5 g increments

- One internal temperature sensor included; depending on version, additional internal humidity, pressure and light sensors

- Replaceable Li-SOCl₂ battery (SAFT LSH 14, 3.6 V, 5.8 Ah), battery lifetime minimum 2 years

- Coloured LED for device status indication

Intelligent data storage

- Shock thresholds adjustable from 0.5 g in defined increments

- Memory capacity of over 2 million measured values

- Ring buffer for up to 1,000 shock events

- Additional memory that can not be overwritten – for relevant shock events exceeding a second threshold

- The MSR175 software package comprises MSR Dashboard for device commissioning, MSR ReportGenerator for automated report generation, and MSR ShockViewer for detailed shock event analysis.

Technical data of the sensors

| Sensors | Working range | Accuracy (max. deviation) | Measurement/Storage rate |

|---|---|---|---|

| 3-axis-acceleration | ±10 g, ±20 g or ±40 g (selectable) (-20…+65 °C) |

4 Hz, 8 Hz, 16 Hz, 31 Hz, 62 Hz, 125 Hz, 250 Hz, 500 Hz, 1000 Hz, 2000 Hz, 4000 Hz

(selectable) |

|

| Temperature | -20…+65 °C | ±0,5 °C (-10…+65 °C) | 10 min./30 min. |

| Relative humidity |

0…100 % rel. humidity (-20…+65 °C) |

±2 % rel. humidity (10…85 %, 0…+40 °C) ±4 % rel. humidity (85…95 %, 0…+40 °C) |

10 min./30 min. |

| Air pressure |

0…2000 mbar absolute (-20…+65 °C) |

±2.5 mbar (750…1100 mbar absolute, +25 °C) |

10 min./30 min. |

| Light | 0…83,000 lx | max. sensitivity at 550 nm | 10 min./30 min. |

| Position | To determine the position, the static acceleration is measured and stored every 10 minutes in all 3 axes. | ||

General technical data of the MSR175Pro data logger

| Memory capacity: | Over 2,000,000 measurement values. |

| Shock events: | 1,000 in ring buffer + 1,000 in additional memory |

| Medium: | Air |

| Colour: | Amber. blue |

| Push button: | Start measurement/retrieve status. |

| Power supply: | Replaceable Li-SOCI2 battery (SAFT LSH 14, 3.6 V, 5.8 Ah), battery operating time 2 years at least. |

| Interface: | USB |

| Software package: | MSR175 Dashboard software, MSR ReportGenerator, free MSR ShockViewer basic version. A fee-based MSR ShockViewer Pro Version will be available at a later stage. System requirements: Windows 7 or higher, USB port. |

| Operating conditions: | |

| Temperature: | -20…+65 °C |

| Storage conditions: | |

| Temperature: Humidity: |

+5…+45 °C (ideal storage condition for the battery) 10…95 % relative humidity, non-condensing |

| Standards: | The MSR175Pro complies with EU-Directives RoHS/WEEE. |

Software

Our PC software is scanned for viruses with Microsoft Defender.

- MSR175 pc software (2025-10-07, v1.02.45, MD5: 9c3786539d25b17ac7cc6ba3b71837ee)

- MSR175 firmware update (2023-07-17, v1.32, MD5: 823e6270eee80d77b4e15aa60ca498f8)

Instructions

- Brief instructions MSR175Pro

- Video tutorials MSR175 Dashboard

- Video tutorial MSR ShockViewer

- Mounting instructions for MSR shock and vibration data loggers

Datasheets

Certificates

- ANA Cargo, Japan, confirmed electronic device list

- Cargolux, approved electronic monitoring devices

- JAL Cargo, Japan, list of approved electronic devices

- RTCA DO-160G ENVIRONMENTAL CONDITIONS AND TEST PROCEDURES FOR AIRBORNE EQUIPMENT SECTION 21, Cat. H

- Certificates Saft LSH14

FAQ – frequently asked questions about MSR data loggers

Monitoring mechanical loads during the transport of power transformers

During the transport of power and large-scale transformers, mechanical loads represent a key risk to operational reliability. Due to their size and mass, transformers are often transported in partial assemblies and only finally assembled at the installation site, resulting in multiple handling and transport stages.

Throughout these processes, the cargo is exposed to shocks, vibrations, tilting and short-duration impact events, which may cause damage that is not visible from the outside. Windings, core structures and insulation systems are particularly sensitive, as even minor displacements or material damage can impair electrical integrity.

The MSR175Pro shock data logger enables continuous monitoring of these mechanical loads throughout the entire transport process. Critical shock events and threshold exceedances are reliably recorded and documented. The measured data provide an objective basis for assessing the transport condition upon arrival at the destination. This allows potential transport damage to be identified at an early stage, responsibilities to be clarified, and risks for subsequent commissioning to be significantly reduced.

The MSR175Pro transport data logger, manufactured with Swiss precision engineering, enables accurate recording of critical events and thereby contributes to sustainable cost reduction.

Where are MSR data loggers with shock sensors used? Read our customer reports:

- CERN, Europäische Organisation für Kernforschung: MSR175plus Datenlogger als Transportdetektive

- Halbleiterhersteller TSMC: Überwachung von Wafer-Transporten mit MSR175plus

- Qingdao Hisense Hitachi Air Conditioning Systems Co., Ltd.: Anwenderbericht Einsatz Datenlogger MSR165

- Weltweit sicher unterwegs: MSR Schock-Datenlogger überwachen Transport von Schleifmaschinen

- Dr. Brüning Engineering UG: MSR175 Datenlogger messen Belastungen bei Falltests

- Transportschäden im Versandhandel – wie vermeiden?

- Kunstmuseum Bern: Transportüberwachung von fragilen Kunstwerken mit MSR175 und MSR165 Datenloggern

MSR transport data loggers in use – customer reports

QINGDAO HISENSE HITACHI USES MSR165 DATA LOGGER TO PREVENT TRANSPORT DAMAGE.

Read More

ORBITAL SCI.: MSR165 DATA LOGGERS MONITOR NASA TRANSPORT

Read MoreWAFER TRANSPORT MONITORING WITH MSR175PLUS DATA LOGGER

Read More

SHOCK DATA LOGGERS MONITOR TRANSPORT OF MACHINES

Read More

MSR165 LOGGERS DETERMINE RAIL TRANSPORTATION COMFORT FOR STADLER RAIL

Read More

CTI RESEARCH PROJECT: PREVENTION STRATEGIES IN THE TRANSPORT OF FRAGILE PAINTINGS

Read More

MSR165 SHOCK LOGGER FOR TEST TRANSPORTS OF FRAGILE PAINTINGS

Read More

UROVIVA: DATA LOGGERS MONITOR TRANSPORT OF MEDICAL EQUIPMENT

Read More

WEGMÜLLER AG: TRANSPORT MONITORING WITH MSR DATA LOGGER

Read More

MONITORING TRANSPORT LOADS WITH MSR DATA LOGGERS

Read More

IPC HORMANN: DATA LOGGERS FOR TRANSPORT MONITORING

Read MoreCERN: TRANSPORT MONITORING WITH MSR175PLUS LOGGERS

Read More